Cryoelectronics and Systems…Continue Reading Cryoelectronics and Systems

Cryoelectronics and Systems

Cryoelectronics and Systems…Continue Reading Cryoelectronics and Systems

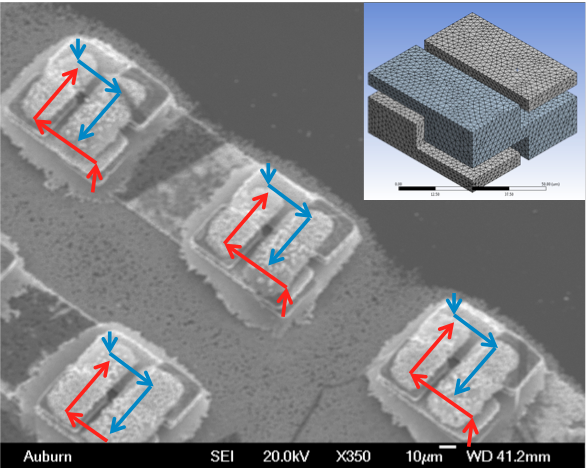

Advanced Interconnects…Continue Reading Reworkable Micro & Nano Interconnects

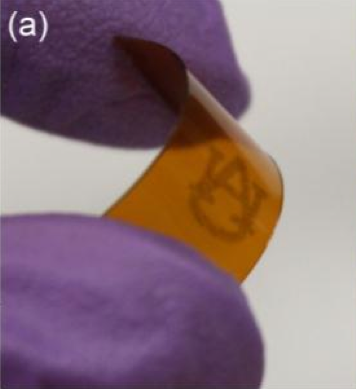

Printed Electronics…Continue Reading Printed and Solution-Based Electronics

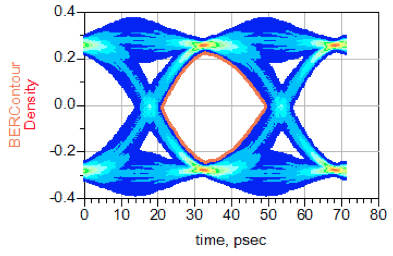

Signal and Power Integrity…Continue Reading SI / PI